Lorraine Koertzen is Category Manager for the SIG Industrial Roofing Centre (IRC) and has been working for this specialist division of SIG for over 10 years.

Based in Manchester, but supporting Industrial Roofing Contractors across the UK, the team at SIG IRC provide impartial advice to help roofers design roofing systems that comply to all building regulations. They offer a pretty unique national service and the team know a lot about Industrial Roofing, so we asked Lorraine “what’s topical in the industrial roofing world right now” and she confirmed the dilema of whether to use a Built-Up or Composite Panel system is now a daily debate they are having with roofing contractors.

Here are her thoughts on the issue…

Built-up or Composite?

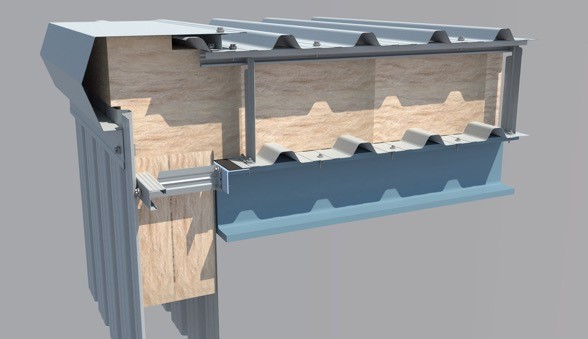

Traditionally, any industrial roof that required insulation would be created by what is now refered to as a ‘Built-Up’ system. Here a liner, bar and bracket, insulation and top metal sheeting would all be laid down separately to create the roof, with individual fixings required for each layer. Overall it did, and still does, offer a customised solution, although it can be a time consuming process where labour costs are invariably high.

Then composite panels were introduced to the market, modular systems that offered the contractor factory bonded panels comprising two metal sheets bonded usually with PIR insulation (polyisocyanurate). They came in different sizes, shapes and colours and became recognised as a product that whilst more expensive to buy, were easier and quicker to fit. It was simply a case of knowing the thickness of panel required, as well as the profile and colour of the top sheet required.

The trajectory of sales for these new composite panels started to overtake all other types of metal roof coverings. It saved roofers time and money and as no special skillsets were required to install these panels, with the skills shortage growing, the panels offered huge benefits for many roofing contractors. Being available for both Roof and Wall applications too, also meant that the full building could be covered in record time.

What’s changed?

Over the past year we’ve seen a growing number of contractors question which is the best system to use on their projects. So, what has changed in the market to create this debate?

Firstly, the investigations, reports and subsequent building regulation changes as a result of the Grenfell disaster have had a huge impact on the market. Not that is was directly relevant to roofing, but expanded foam is present in many composite panels and in some projects contractors are now seeking higher ‘integrity’, non-combustible options like mineral wool which are not readily available in panels.

The qualities of a panel are measure in ‘Integrity’ which is the length of time it takes for the panel to show damage from fire and is usually measured in minutes (30,60,90,120 & 240 minutes) in theory the length of time you have to exit a building that is on fire. Plus ‘U-Values’ which is the rate at which heat is transferred through the panel, the better the resistance the lower the U Value (U is the symbol for Internal Energy).

The growing green movement is also having an effect as there are some composite panels which are recyclable or contain some recycled materials and use different chemicals within the insulation to improve the fire resistance of the product, but very few panels can meet the most stringent insulation and non combustible requirements. Any that come close are usually very heavy to lift and that in itself can cause problems with off loading and labour resources on site. On many refurbishment projects the weight of the product alone can eliminate it from consideration for the building project.

The drive for solar panels to be fitted to industrial roofs is also a new sustainable consideration. Can the building sustain the additional weight? And currently only one supplier of metal sheeting has confirmed that their warranties will cover the coating if solar panels are fitted. Coating warranty implications should be considered if any Solar project is being retrofitted to an Industrial roof.

The bespoke benefits of a built-up system allow for different top sheet coatings and types of insulation to be used and the weight of the individual components are lighter to move around on site. So whilst it may be a more lengthy process to install, it can offer peace of mind to the end user who is usually the standard setter.

Finally, there was also some confusion created when the BRE removed the LPCB certification from Kingspan products, Although full insurance backed cover from FM Global giant was never in question and the BRE quickly reinstated the LPCB status on all Kingspan products, for some contractors it raised a question on all types of PIR insulated panels.

So there has been a collection of recent changes and conversations in the market that have resulted in the roofing contractor having to decide what is the best product to use for a particular project and the best system, be it Built-Up or Composite Panels.

How can SIG IRC help?

At SIG IRC our job is to help our customers to consider the options, once we understand the requirements of the roof and building. We need to understand what they are trying to achieve with a particular project and we then go through a check list to discount or add certain possibilities.

There are so many different elements to consider with either a new or refurbished industrial roof. Does the building need insulation and to what level? What is the building being used for or converted to? What substructures are currently in place? Is air leakage or noise reduction a consideration? If an over-roofing project is being considered, does the incumbent roof contain asbestos? What weight considerations need to be looked at? is it possible to over roof? Will solar installations be a requirement?

At SIG IRC we deal with all manufacturing suppliers of Industrial Roofing products so we can offer our contractor customers totally unbiased advice on what product options they have.

As a distributor we have no preference as to what products a contractor wishes to use for a project we just want to help get the right product at the right price for the right project, right first time.

If a customer requires it we can can provide two options and outline the benefits of each to help the contractor be better informed to make the choice.

Sometimes on projects without Architectural input the decision comes down to personal preference of the contractor as some contractors still prefer Built-Up over Composite installations. Other times it will come down to which offers the best performance or price for that job.